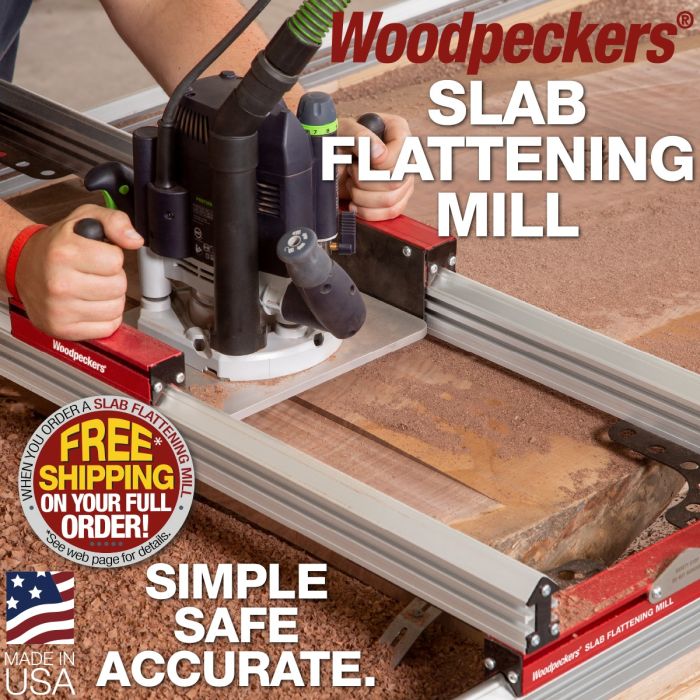

Woodpeckers Slab Flattening Mill

Square and Flatten Live Edge Slabs for Perfect Designs

The hottest trend in interior design these days is live edge slabs. And, why not? The natural curves of the trunk give an organic feel. The crazy grain patterns in crotches and burls are eye-catching. Even cracks that would have sent lumber to the burn pile just a few years ago are being controlled and enhanced with butterfly patches and epoxy inlays. However, slabs present some challenges in the shop. Overall width and weird grain changes make the use of a jointer and thickness planer impractical if not impossible. But now you can accurately flatten live-edge slabs and other oversized stock faster and easier than you ever thought possible with Woodpeckers Slab Flattening Mill.

![]()

Choose Buy Now/Pay Later At Checkout - Learn More

SLAB FLATTENING MILL

Woodpeckers Slab Flattening Mill guides your router over your slab in a controlled plane. Since you’re using a router instead of a planer-style cutterhead, tear-out is minimal…the surface will only need light sanding afterwards. The Slab Flattening Mill starts with two aluminum extrusions. The inverted “V” shape of these main rails sheds sawdust and provides a solid base for the mating extrusion. The second extrusion fits over the inverted “V” and glides on UHMW polyethylene runners. Simply mount the mill to any flat and level work surface…even a sheet of MDF on a pair of sawhorses. When you’re done, the modular design stores conveniently.

We now offer the Slab Flattening Mill in 3 sizes to accommodate the needs of every slab woodworker. If you’re tight on shop space and are planning to do end-grain cutting boards and end-table-sized slabs, our smallest Slab Flattening Mill will handle work up to 24" x 48". The Basic Slab Flattening Mill accommodates slabs up to 38” x 57”. The Extended Slab Flattening Mill adds an additional pair of 72" rails that can either replace the cross rails to increase width, or connect with the base rails to extend length. The capacity grows to either 62” x 105” or 38” x 129”. These huge capacities are great…when you need them. Remember, though, you can always mount the rails closer together when it suits your project. See the chart in the photos for a guide to all the maximum size configurations. All sizes of the Slab Flattening Mill can accommodate stock up to 3-7/16" in thickness. If your stock is thicker than that, you can use shop-made spacers to raise the Slab Flattening Mill. Conversely, if you are dealing with thin stock, you can use the same approach on the underside of your thin stock. Since all routers vary in height capacity and router bits vary in overall length, you may need to elevate your stock or elevate the mill in order to achieve the desired results of the Slab Flattening Mill.

Using the Slab Flattening Mill is as easy as sliding your router across the slab and back, moving over a little less than the width of your cutter and repeating until you’re done. It works best with a variable speed router of 2 horsepower or more. You’ll get done sooner if you stick to a large diameter spoil board style bit. We’ve done some of the shopping for you and offer a couple of suggested router bits. One is an economical brazed carbide bit from Whiteside. The second one, from Amana, features reversible/replaceable carbide inserts so you can always have sharp edges.

This process produces lots of shavings. Our new optional dust collection port bolts to the carriage and rides along right beside the exit point of the shavings. It works with either shop vacuums or larger dust collectors. A brush surrounds the pick-up area, trapping the shavings equally well on smooth or uneven slab surfaces. Mounts to the carriage with 6 simple screws, replacing the carriage end-stops. This will retro-fit to any Woodpeckers Slab Flattening Mill, regardless of when you bought it.

Don’t put off that natural edge project you’ve been dreaming about any longer. Order your Woodpeckers Slab Flattening Mill today!

Protected by US PATENT No. D930,451 11,685,075 D899,473 & 11,685,076.

| Country of Manufacture | United States |

|---|

Slab Flattening Mill - FAQ

Q: Can I expand the overall dimensions of the Slab Flattening Mill?

A: Yes, you can purchase extension rails in varying lengths of 24”, 48”, 72”, and 76”.

Q: Is there a way to increase the thickness of a slab I can mill?

A: You can secure 2”x4” or 4”x4” lumber to the base and then secure the base rails to the lumber which allows you to mill thicker slabs.

Q: Can I order a specific length of V-Rail?

A: Unfortunately, we are not able to provide any other length than what is advertised on our website.

Q: What is the difference between the Board Mill, Slab Flattening Mill, and the Slab Flattening Mill PRO?

A: The board mill is designed to be used for flattening and milling thinner boards from ¾” to 1-¾” thick with a width capacity of 18” and length of 55-¾”. The Slab Flattening Mill can mill slabs up to 3-7/16” and the minimum thickness depends on the travel of the router and length of the blade. The Slab Flattening Mill can mill boards up to 40-¾” in width and 58-⅜” in length. The Slab Flattening Mill PRO is able to mill slabs and boards as thin as ¾” and as thick as 3-3/8''. With a capacity of 49” in width and 58” in length. The other big difference is that the Board Mill and the Slab Flattening Mill PRO have integrated dust collection with a dust curtain and ports where the Slab Flattening Mill will need to have the Dust Collection Shroud used which can be purchased separately.

-

Amana Tool Router Bit ExtensionSpecial Price $49.99 Regular Price $79.80

Amana Tool Router Bit ExtensionSpecial Price $49.99 Regular Price $79.80