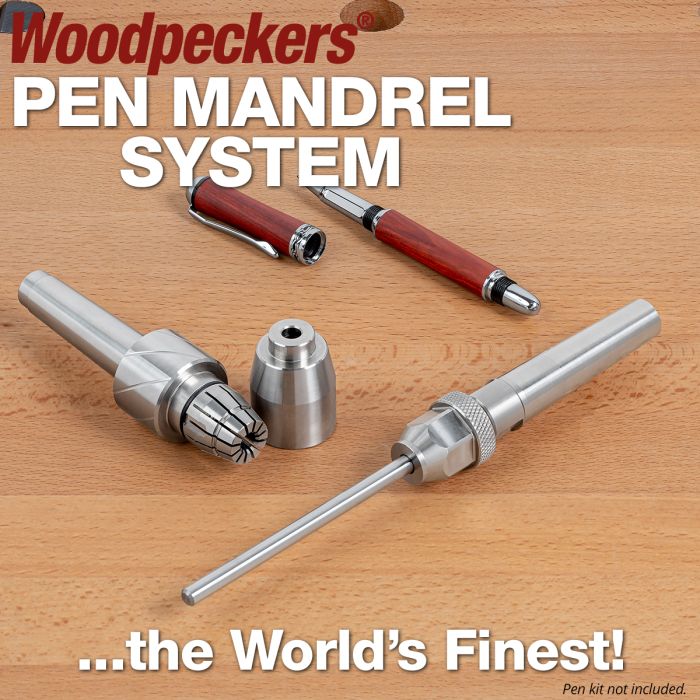

Pen Mandrel System and Precision Pen Turning Bushings

If you’ve turned more than a couple pens, you’ve probably noticed that there’s just not much material left on top of the brass tube when you get finished. Any amount of misalignment can show up as brass showing through acrylic or even worse, a complete blow-out. None of the mandrels available on the market today seem to help matters much, until now. Introducing the Pen Mandrel System. Each component is designed and manufactured with one goal…keeping your pen perfectly centered on your lathe.

Ultra-Shear Pen Mandrel System and Precision Pen Turning Bushings

Let’s start at the headstock side. The mandrel shaft slides into a 12-segment collet. Expose just the amount you need and close the collet with the locking collar. The shaft is perfectly centered and locked securely. The mandrel utilizes a #2 morse taper.

The ground and polished mandrel shaft accommodates almost all bushings on the market, including our new precision bushings (more on them later).

On the tailstock side, the mandrel shaft goes into another 12-segment collet…don’t worry about putting in extra spacers to take up the unused shaft, just slide your tailstock right up tight to your work. As you tighten your tailstock, the cap compresses the collet, centering the mandrel shaft perfectly.

While we were designing the world’s best pen mandrel, we decided to make the world’s best bushings to go along with it. Our Precision Pen Bushings are more durable and fit the mandrel shaft and the tube diameter better than any others out there and match the pen kit specs for outside diameter to the strictest tolerance. Unlike ordinary bushings, Woodpeckers Precision Pen Bushings are turned from hardened stainless steel, and engraved with their part number so you won’t have to guess about which bushing goes with what kit. The portion that fits inside the pen blank is longer, providing additional support, and the bushings for two-piece pens are clearly marked to mate up with your blanks correctly.

We also turned a wear groove in the bushing just back from where it enters the pen blank. As long as you can see that groove, your bushing isn’t worn out and will give you perfect alignment of the turned pen to the kit components. After a mountain of finished pens, when the wear groove is gone, you’ll know it’s time to get a new bushing set.

You won’t find another mandrel on the market that centers your work more precisely. Every piece of the system is manufactured to the strictest tolerances, from the finest stainless steel available, on state-of-the-art CNC Swiss Lathes.

Just like the Pen Mill and our famous turning tools, Woodpeckers Pen Mandrel System and Precision Pen Bushings are precisely machined and carefully inspected at our factory in Strongsville, Ohio (just south of Cleveland).

Protected by US PATENT NO. D971,279 & 11,701,790

| Country of Manufacture | United States |

|---|

FREQUENTLY ASKED QUESTIONS

Q: What size allen key is needed for the turning tools?

A: The Full-size and Mid-Size Turning tool sets take a 1/16” or 3/32”, and the Pen size uses a 1/16”.

Q: How do I remove my difficult to loosen cutter screw?

A: Make sure the screw head pocket is completely clean of sawdust and residue to ensure that the wrench is fully seated in the socket before you attempt to remove it. This will give you full contact between the wrench and screw and will make removal easier. Firmly turn the screw counter clockwise to loosen. When reinstalling the new screw, apply a light dab of anti-seize compound to the threads.