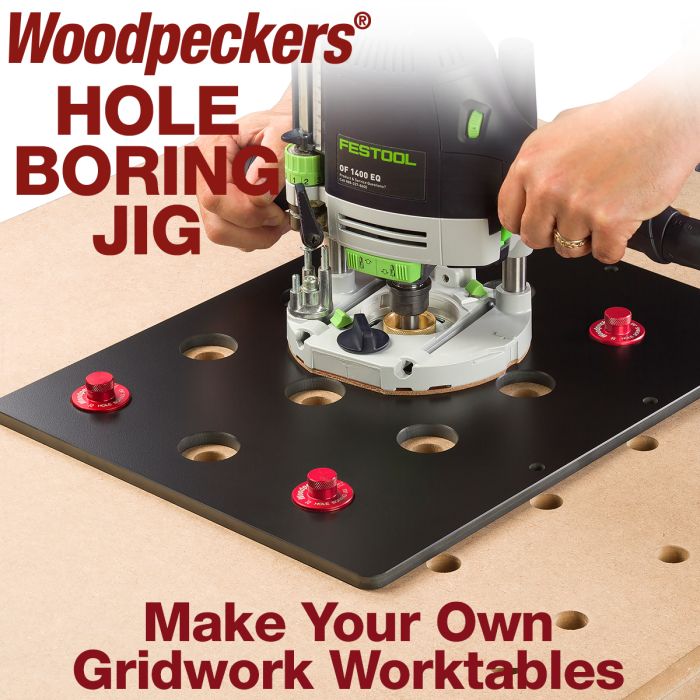

Hole-Boring Jig

Make your own gridwork workbench top…for a fraction of the cost of a ready-made top…with Woodpeckers Hole Boring Jig. Whether you’re building a custom work table or replacing the top on a Festool MFT, you can mill the top with near-CNC accuracy with nothing fancier than a good router, a sharp bit and the Hole Boring Jig. Woodworkers around the world have embraced the idea of a work surface milled with a gridwork of holes. Dozens of companies (including Woodpeckers!) produce devices that fit into the grid to hold your work. Now you can add a gridwork clamping surface to any countertop or assembly table in your shop.

Woodpeckers Hole Boring Jig

Woodpeckers Hole Boring Jig is a 3/8" thick solid phenolic, CNC-machined template. Index pins placed against the corner of your table position the template for the first group of holes. Then, you’ll use the already-milled holes to index across the rest of the table surface. All you need is a router that accepts Porter-Cable style guide bushings and a 1/2" straight router bit (our variable helix up-cut bits are the best choice).

Two standards have developed for these table tops. Festool uses 20mm holes while Veritas and a few others use 3/4" holes. Woodpeckers has you covered no matter which standard you use because you get the guide bushings and index pins for both hole sizes.

For less than the price of one replacement top for a Festool MFT, you can get the jig, make your own replacement top and then start adding gridwork tops for the other work surfaces in your shop. With an array of clamps and end-stops there’s no limit to the workholding arrangements you can set up on a gridwork table.

Like all Woodpeckers products, the Hole Boring Jig is precisely machined and carefully inspected in our Strongsville, Ohio facility just south of Cleveland.

| Country of Manufacture | United States |

|---|